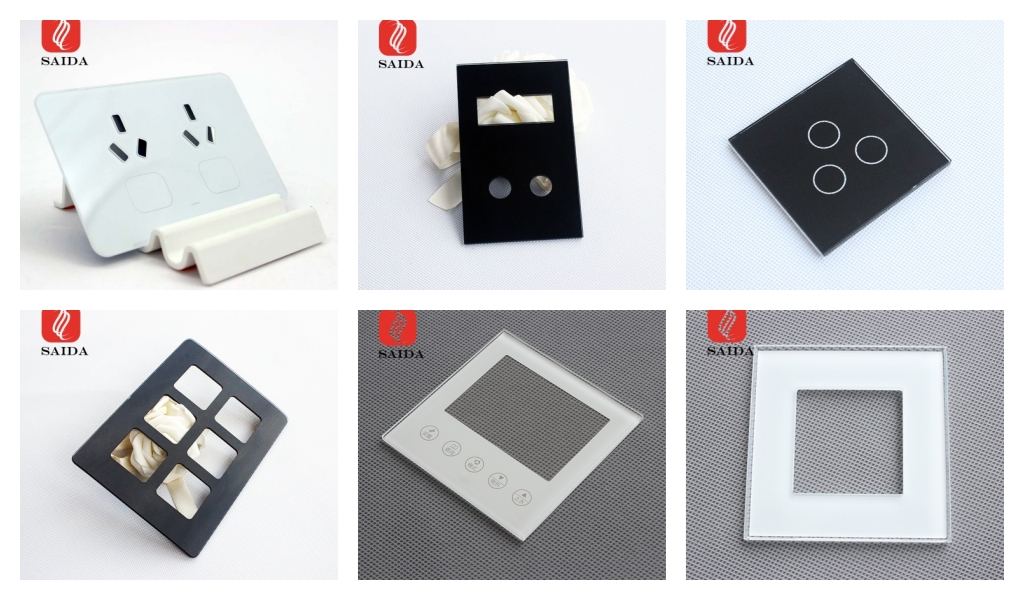

❓ How Is Glass Used in Switch Panels?

Glass is everywhere in modern smart homes — from display screens to appliance covers — and switch panels are no exception. High-quality glass is essential for durability, safety, and design, making it a key component in smart home and control systems.

Precision Thickness for Every Application

Switch panel glass typically comes in precise thicknesses:

-

1.1 mm (ultra-thin panels)

-

2.0 mm

-

3.0 mm

-

4.0 mm

-

5.0 mm

-

6.0 mm

Which Glass Materials Are Commonly Used?

-

Soda-lime glass: Easy to produce, high hardness, not heat-resistant.

-

Ultra-clear glass: High light transmittance, low color deviation, and crystal-clear surface.

-

High-alumina glass: High strength and scratch resistance for high-reliability applications.

What Edge and Shape Processing Options Are Available?

-

Double-sided grinding and edge polishing

-

CNC rounded corner processing

-

2.5D and pseudo 3D edge profiles

-

Complex and fully customized geometric shapes

How Is the Glass Strengthened?

-

≥3.0 mm: Fully tempered glass

-

2.0 mm: Semi-tempered glass

-

Aluminosilicate glass: Chemical strengthening

What Printing and Surface Treatments Are Available?

-

Low- and high-temperature screen printing

-

Multi-color printing

-

Surface treatments including glossy, anti-glare (AG), and etched matte finishes

What Adhesives, Laminations, and Functional Openings Can Be Integrated?

-

3M adhesives (468MP / 300LSE / VHB series)

-

Diffusion films and diffusion paper

-

Functional openings such as socket cutouts, RJ45 interfaces, and multi-hole power designs

Why Saida Glass?

With over 13 years of experience in precision glass deep processing, automated production lines, and strict quality management systems, Saida Glass delivers high-precision, customizable glass solutions for switch panels — combining durability, aesthetics, and functionality.