What is TCO glass?

The full name of TCO glass is Transparent Conductive Oxide glass, by physical or chemical coating on glass surface to add a transparent conductive oxide thin layer. The thin layers are composite of Indium, tin, zinc and cadmium (Cd) oxides and their composite multi-element oxide films.

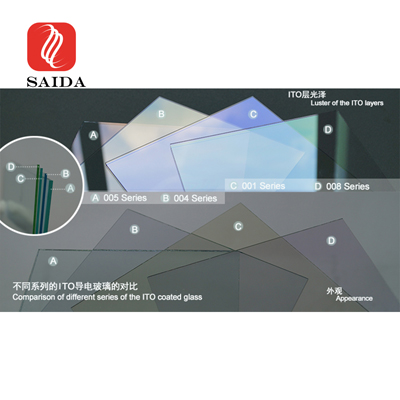

There are 3 kinds of conductive glass, ITO conductive glass (Indium Tin Oxide Glass), FTO conductive glass (Fluorine-doped Tin Oxide Glass) and AZO conductive glass (Aluminum-doped Zinc Oxide Glass).

Among them, ITO coated glass can only be heated to 350°C, while FTO coated glass can be heated up to 600°C, which has good thermal stability and weather resistance, with the high light transmittance and higher reflectance in infrared zone, which has become the mainstream choice for thin-film photovoltaic cells.

According to the coating process, TCO glass is divided into online coating and offline coating TCO glass.

Online coating and glass production are carried out at the same time, which can reduce additional cleaning, reheating and other processes, so the manufacturing cost is lower than offline coating, the deposition speed is faster, and the output is larger. However, as the process parameters cannot be adjusted at any time, the flexibility is less to choose.

The off-line coating equipment can be designed in a modular manner, formula and process parameters can be adjusted according to customer needs, and production capacity adjustment is also more convenient.

|

/ |

Technology |

Coating Hardness |

Transmittance |

Sheet Resistance |

Deposition speed |

Flexibility |

Equipment & Manufacturing Cost |

After coated, can do tempering or not |

|

Online coating |

CVD |

Harder |

Higher |

Higher |

Quicker |

Less flexibility |

Less |

Can |

|

Offline coating |

PVD/CVD |

Softer |

Lower |

Lower |

Slower |

Higher flexibility |

More |

Can’t |

However, it should be noted that from the perspective of the whole life cycle, the equipment for online coating is highly specialized, and it is difficult to change the glass production line after the furnace is put into operation, and the exit cost is relatively high. The current online coating process is mainly used to produce FTO glass and ITO glass for thin-film photovoltaic cells.

Except the standard soda lime glass substrates, Saida Glass are able to apply the conductive coating on low iron glass, borosilicate glass, sapphire glass as well.

If you are in need of any projects like above, freely drop an email via Sales@saideglass.com or directly call us +86 135 8088 6639.